| Business Type | Exporter, Supplier |

| Specialities | Non Breakable, High Quality |

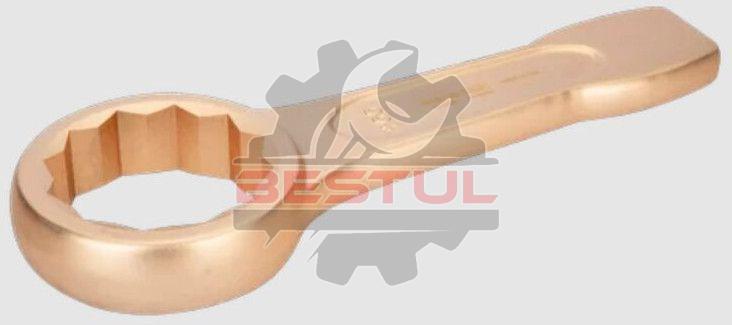

| Type | Ring Spanner |

| Material | Cast Iron |

| Click to view more | |

Product Details

A sparkless slogging ring spanner, also known as a spark-resistant slogging wrench, is a specialized tool designed for heavy-duty applications in environments where avoiding sparks is essential, such as in hazardous or explosive atmospheres. The term "slogging" refers to the use of a tool with a striking force, typically used with a hammer or mallet. Here’s a detailed overview of this tool:

Features and Design

-

Spark-Resistant Material:

- Material Composition: Made from non-ferrous materials such as beryllium copper or aluminum bronze, which are selected for their spark-resistant properties. These materials prevent the generation of sparks during use.

- Properties: Designed to minimize the risk of igniting flammable gases, vapors, or dust in hazardous environments.

-

Slogging Ring Design:

- Ring Head: The slogging ring spanner features a ring-shaped head designed to fit over nuts and bolts. The ring is typically a six-point or twelve-point design to provide a secure grip and reduce the risk of rounding off the fastener.

- Slogging Use: The tool is built to withstand the impact of being struck with a hammer or mallet, making it suitable for heavy-duty applications where high torque is required.

-

Construction:

- Strength and Durability: Constructed from robust, high-strength alloys to handle the stresses involved in heavy-duty applications. The tool is designed to be durable and long-lasting.

- Finish: Often treated to resist corrosion and wear, maintaining performance over time in demanding conditions.

-

Comfort and Ergonomics:

- Handle: The handle is designed for durability and may include features to enhance grip and control during use. Although ergonomics are less emphasized in slogging tools compared to precision tools, ensuring a comfortable grip can still be beneficial.

Applications

-

Hazardous Environments:

- Flammable or Explosive Atmospheres: Ideal for use in industries such as oil and gas, mining, and chemical processing, where avoiding sparks is crucial to prevent explosions or fires.

- Safety: Ensures that tools used in potentially dangerous environments do not generate sparks, enhancing overall safety.

-

Heavy-Duty Maintenance and Repair:

- Equipment and Machinery: Used for tasks that require high torque and where traditional wrenches may not be sufficient. The slogging spanner can handle tough, stubborn fasteners.

-

Industrial and Construction Work:

- Worksites: Suitable for construction and industrial applications where heavy-duty tools are needed and where spark prevention is important.

Usage Tips

-

Inspect Before Use: Regularly check the slogging spanner for any signs of damage, such as cracks or wear. Damaged tools should be replaced to ensure safety and effectiveness.

-

Proper Handling: Use the tool according to manufacturer instructions. The spanner is designed to be struck with a hammer or mallet, so use it with appropriate striking tools and techniques.

-

Storage: Store the spanner in a clean, dry environment to prevent corrosion and damage. Avoid exposure to harsh chemicals or extreme temperatures.

-

Cleaning: Clean the spanner with non-abrasive methods. Ensure that the tool is free from debris and contaminants that could affect its performance.

-