Industrial Wrenchs

Leading Exporters, Wholesaler, Manufacturers, Importer and Trader of BTX-4 Hydraulic Hex Type Torque Wrench 640Nm To 6480Nm, Digital Torque Wrench, DPB22C Dongcheng Electric Wrench, DPB30 Dongcheng Electric Impact Wrench, Gedore Friction Wrench, Gedore Light Weight Torque Wrench Dremometer Dl 3/4, Gedore Torque Wrench, Hydraulic Square Drive Torque Wrench 450NM To 4520 NM, Hydraulic Square Drive Torque Wrenches 6925Nm To 69247Nm, Hydraulic Torque Wrench, Hydraulic Torque Wrench Hex, Hydraulic Torque Wrench Hex Drive Direct Fit, Insulated Open Wrench, Mac Master Torque Wrench, Non Sparking Adjustable Wrenches, Non Sparking Bung Wrench, Non Sparking Pipe Wrench, Open End Crowfoot Wrench, Open End Slugging Wrench, Ridgid Aluminium Pipe Wrench, Ridgid Chain Pipe Wrench and Ridgid Chain Wrench from Mumbai.

| Business Type | Exporter, Supplier |

| Material | MildSteel |

| Color | Silver |

| Size | Multisizes |

| Packaging Type | Box |

| Specialities | High Quality |

| Country of Origin | India |

| Rust Proof | Yes |

| Business Type | Exporter, Supplier |

| Drive Size | 1/2 Inch |

| Material | Mild Steel |

| Brand Name | Mac Master |

| Socket Type | Impact Socket |

| Warranty | 1 Year |

| Application | Industrial |

| Packaging Type | Box |

| Air Consumption | 6 bar |

| Max Torque | 8000 Nm |

| Country of Origin | Made in India |

we are the leading suppliers in this industry we cater all types of client all over india we provide products in bulk and at best price possible.

| Business Type | Exporter, Supplier |

| Power Consumption | 200 watts |

| Power Consumption (Watt) | 50 W |

| Warranty | 1 Year |

| No Load Speed | 1700 r/min |

| Weight | 5 KG |

| Torque Range | 588 NM |

| Application | Bolt Tightening |

| Drive Size | 19X19MM |

| Bolt Capacity | M16mm-M22mm |

An electric wrench, also known as an electric impact wrench, is a power tool designed to quickly and efficiently tighten or loosen nuts and bolts. It utilizes rotational force (torque) to achieve this, making it an essential tool in automotive repair, construction, and various mechanical applications where fastening or loosening large or stubborn fasteners is required.

Here are some key features and points about electric wrenches:

Power Source: Electric wrenches are typically powered by electricity, either through a corded connection to an electrical outlet or by using rechargeable batteries. The cordless battery-powered models offer greater mobility and convenience, while corded models provide consistent power without the need for recharging.

Torque Output: Electric wrenches come in various torque output levels, ranging from lower torque suitable for smaller fasteners to higher torque for heavy-duty applications.

Impact Mechanism: These wrenches use an impact mechanism that generates both rotational force and rapid hammer-like impacts. This combination helps break loose tight fasteners that might be challenging to remove with traditional manual wrenches.

Variable Speed and Direction: Many electric wrenches offer adjustable speed and direction settings. Variable speed control allows for precision and prevents over-tightening, while reversible direction allows both tightening and loosening of fasteners.

Socket Attachments: Electric wrenches use socket attachments that come in various sizes to match different types of nuts and bolts.

Applications: Electric wrenches are commonly used in automotive repair, construction, manufacturing, and maintenance tasks where large and tight fasteners need to be dealt with efficiently. They're particularly valuable in situations where time is of the essence.

Safety Considerations: While electric wrenches are powerful and efficient, users need to be cautious about using the correct torque settings to avoid damaging fasteners or components. Over-tightening can lead to stripped threads or other damage.

Maintenance: Regular maintenance, such as cleaning and lubrication, is important to ensure the longevity and proper functioning of an electric wrench.

As for specific models or brands, my knowledge is based on information available up until September 2021. If you're interested in a particular electric wrench model, I recommend checking the manufacturer's website, product manuals, online retailers, and reviews to gather more detailed and up-to-date information

| Business Type | Exporter, Supplier |

| Type | Electric Impact Wrench |

| Warranty | 1 Year |

| No Load Speed | 1400r/min |

| Weight | 10Kg |

| Torque Range | 400-900Nm |

| Application | electric impact wrench is a power tool used for tightening or loosening nuts and bolts quickly |

| Country of Origin | Made in India |

An electric impact wrench is a power tool used for tightening or loosening nuts and bolts quickly and efficiently. Unlike traditional wrenches, which require manual effort, electric impact wrenches utilize electricity to generate high torque output, making them ideal for tasks like automotive repair, construction, or maintenance work.

These tools typically feature a motor that drives a rotating hammer mechanism, which delivers rapid, repetitive impacts to the output shaft. The impact action allows the wrench to exert much greater force compared to manual wrenches, enabling fastening or unfastening of stubborn or tightly secured fasteners.

Electric impact wrenches are available in various sizes and power ratings to suit different applications, from small household tasks to heavy-duty industrial use. They are commonly used in automotive repair shops, construction sites, and manufacturing facilities where speed and efficiency are essential. When choosing an electric impact wrench, factors to consider include power output, torque rating, size, weight, and any additional features such as variable speed settings or ergonomic design

| Business Type | Exporter, Supplier |

| Brand Name | Gedore Germany |

| Color | Dark Grey |

| Model Name/Number | 6256120 |

| Size/Dimension | 20" |

| Usage/Application | Bolt Tightening |

| Type | Friction Type Ratchet |

| Size | Bi-Hex Ring 36mm |

| Finishing | manganese-phosphate. |

| Specialities | Friction Type Ratchet with Ring |

| Material | vanadium steel 31CrV3 |

Friction Type Ratchet with Ring

Friction spanner (31 K) with exchangeable UD profile or bi-hexagon insert rings (31 R).

Flat shaft up to 30", push-fit tube handle from 35".

GEDORE vanadium steel 31CrV3, manganese-phosphated.

| Business Type | Exporter, Supplier |

| Material | Aluminium |

| Drive Size | 3/4 Inch |

| Model Name | Gedore 8563-10 Torque Wrench DREMOMETER D 3/4" 155-760 Nm |

| Specialities | Precision, Durability, Versatility, Ease Of Use, High Torque Range |

| Usage/Application | Automotive Repairs, Construction, Industrial Applications |

| Click Mechanism | Audible Click At Preset Torque |

| Storage And Carrying Case | Included For Protection And Transportation |

The term "Dremometer" likely comes from a combination of "Drehmoment," which is German for torque, and "meter," emphasizing its function as a torque-measuring tool.

Here are some features you might find in Gedore Dremometer torque wrenches:

-

Accuracy: These torque wrenches are designed to provide precise and reliable torque measurements, crucial for tasks where accuracy is paramount.

-

Durability: Gedore tools, in general, are known for their durability. The Dremometer series is likely no different, with materials and construction geared towards longevity.

-

Versatility: Depending on the model, Gedore Dremometer torque wrenches may have a wide torque range, making them suitable for various applications.

-

Ease of Use: Look for features like an easy-to-read scale and possibly a click or digital mechanism to signal when the preset torque value is reached.

-

Applications: These torque wrenches could be used in automotive repairs, construction, or any situation where precise torque is essential to ensure the proper functioning of components.

-

Drive Size: The 3/4" drive size indicates the size of the square end of the torque wrench that fits into the socket. A larger drive size like 3/4" is often used for heavy-duty applications, providing more torque capacity.

-

Torque Range: The torque range of 140-760 Nm (Newton-meters) is quite extensive. This means the wrench is suitable for a wide range of tightening or loosening tasks, from lighter applications to heavy-duty ones.

-

Adjustability: These torque wrenches are likely adjustable, allowing you to set the desired torque value for your specific task. Some models may have a locking mechanism to secure the chosen torque setting.

-

Materials: Given Gedore's reputation, the materials used in the construction of the Dremometer are likely of high quality. This ensures durability and reliability in various working conditions.

-

Application: With its torque range, this wrench is versatile and can be used in diverse fields such as automotive repair, construction, or any industry where accurate torque application is crucial.

-

Accuracy: Gedore torque wrenches typically aim for high precision, ensuring that the specified torque is applied accurately, which is particularly important in situations where overtightening or undertightening can cause issues.

Remember to follow the manufacturer's guidelines for calibration and maintenance to keep your torque wrench performing at its best. Is there anything specific about this torque

-

Scale Type: Depending on the model, the Dremometer torque wrench may have a traditional analog scale or a digital display. The scale indicates the applied torque, and the digital display provides a precise numeric readout.

-

Click Mechanism: Many torque wrenches, including Gedore Dremometer models, use a click mechanism. When the preset torque value is reached, the wrench emits a distinct click sound, signaling you to stop applying force. This helps prevent over-torquing.

-

Ratcheting Head: The ratcheting head allows for continuous rotation in one direction while preventing rotation in the opposite direction. This feature is handy for tasks where you need to maintain a consistent torque application.

-

Storage and Carrying Case: To protect your torque wrench when not in use and during transportation, Gedore often provides a storage or carrying case. This ensures that your tool stays in optimal condition.

-

Calibration Certificate: Some torque wrenches, especially those used in professional settings, may come with a calibration certificate. This document verifies that the torque wrench has been tested and meets the specified accuracy standards.

-

| Business Type | Exporter, Supplier |

| Drive Size | 3/4 Inch |

| Brand Name | GEDORE |

| Model Number | 8574-10 |

| Overall Length | 812 |

| Warranty | 6 months |

| Usage | Industrial |

| Material | Aluminium |

| Torque Range | 110-550 |

| Type | Gedore Torque Wrench |

| Country of Origin | Made in India |

TORQUE WRENCH DREMOMETER AM - F 6-3000 N·m Use: T Controlled screw tightening in the range 6 - 3000 N·m T For use in almost all industrial manufacturing areas Features: T Classifi ed to DIN EN ISO 6789:2003 Type II Class A, with a factory certifi cate. Working accuracy: +/- 3 % tolerance of scale set torque. The specifi cation of the standard (+/- 4 %) is exceeded. T Automatic short-path actuation with tactile impulse and audible signal T Dual scale (except for type E-F) with corresponding scale graduation (see table) T Type B, BC, C with push-button release T Type BCK with integrated ratchet function Technical advantage/Function: T Lightweight and robust (as housing is made of an aluminium alloy), very workshop-friendly T No inaccuracies whether used with both hands or held away from the handle (as for standard torque wrenches) Both the square drive and fulcrum are on an axis which ensures a high degree of user safety; can be extended to reduce the user''s working load. T Extremely low wear attributable to reduced forces in a unique lever mechanism T Forged lever chain from our own quality forge T Maximum precision even when subjected to extreme continuous use T Long life cycles and tool lives T Easy operation - fast and safe torque tightening T Easy adjustment thanks to attractive adjusting button secured against loss at the end of the handle T Single- and double-square drive for controlled bi-directional tightening

| Business Type | Exporter, Supplier |

| Drive Size | 3/4 Inch |

| Brand Name | Powermaster |

| Usage/Application | Hydraulic square drive torque wrenches are heavy-duty used for applying a precise amount of torque |

| Color | Silver |

| Material | Aluminium Body |

| Country of Origin | Made in India |

Hydraulic square drive torque wrenches are heavy-duty tools used for applying a precise amount of torque to fasteners in various industrial applications. They are designed for use in situations where high torque values are required, such as in construction, maintenance, and equipment assembly. Here's a bit more detail about them:

Key Features:

- Hydraulic Power: The wrench uses hydraulic pressure to generate torque, making it efficient for high-torque applications without requiring excessive manual effort.

- Square Drive: The square drive allows the tool to fit standard socket sets, making it versatile for different fasteners and bolt sizes.

- Accuracy: These wrenches are known for their accuracy in delivering consistent torque values, often with an integrated gauge or digital readout for precise measurements.

- Durability: They are built for tough, heavy-duty tasks and are commonly used in industries such as oil and gas, manufacturing, and construction, where high torque is needed for tasks like assembling large equipment or tightening bolts on heavy machinery.

- Safety: The hydraulic system ensures smooth operation with controlled force, reducing the risk of damage to the fastener or surrounding components.

Applications:

- Heavy Equipment Maintenance: Used for tightening or loosening bolts on large machinery and equipment.

- Oil and Gas Industry: For flanged connections, valve assembly, and pipeline work.

- Construction: Tightening bolts on steel structures, large beams, or bridges.

- Automotive/Marine: Torqueing large bolts for vehicle or ship assembly.

Hydraulic square drive torque wrenches operate based on the principles of hydraulic pressure and mechanical leverage. Here’s a breakdown of their working mechanism:

- Hydraulic Pump: The wrench is typically powered by a hydraulic pump, which generates pressure. This pump is either manually operated, driven by an electric motor, or powered by air.

- Hydraulic Cylinder: The pump pressurizes the hydraulic fluid, which then drives a piston inside the hydraulic cylinder. The piston applies force to the internal drive mechanism of the wrench.

- Torque Generation: This force is transmitted through the wrench’s square drive, which rotates the attached socket. The amount of torque generated is directly proportional to the hydraulic pressure applied, and the system is calibrated to provide accurate readings.

- Control Mechanisms: Many hydraulic torque wrenches are equipped with torque control systems (manual or digital) that allow the user to set a desired torque value. When this value is reached, the wrench may automatically stop or give a visual or audible signal to prevent over-tightening.

- Release Mechanism: Once the set torque level is achieved, the system will release or disengage, ensuring the exact torque value is applied.

| Business Type | Exporter, Supplier |

| Drive Size | 3/4 Inch |

| Brand Name | Powermaster |

| Usage/Application | Hydraulic square drive torque wrench are used for applying a precise amount of torque |

| Model Name/Number | BTS-50 |

| Color | Yellow |

| Country of Origin | Made in India |

Hydraulic square drive torque wrenches are heavy-duty tools used for applying a precise amount of torque to fasteners in various industrial applications. They are designed for use in situations where high torque values are required, such as in construction, maintenance, and equipment assembly. Here's a bit more detail about them:

Key Features:

- Hydraulic Power: The wrench uses hydraulic pressure to generate torque, making it efficient for high-torque applications without requiring excessive manual effort.

- Square Drive: The square drive allows the tool to fit standard socket sets, making it versatile for different fasteners and bolt sizes.

- Accuracy: These wrenches are known for their accuracy in delivering consistent torque values, often with an integrated gauge or digital readout for precise measurements.

- Durability: They are built for tough, heavy-duty tasks and are commonly used in industries such as oil and gas, manufacturing, and construction, where high torque is needed for tasks like assembling large equipment or tightening bolts on heavy machinery.

- Safety: The hydraulic system ensures smooth operation with controlled force, reducing the risk of damage to the fastener or surrounding components.

Applications:

- Heavy Equipment Maintenance: Used for tightening or loosening bolts on large machinery and equipment.

- Oil and Gas Industry: For flanged connections, valve assembly, and pipeline work.

- Construction: Tightening bolts on steel structures, large beams, or bridges.

- Automotive/Marine: Torqueing large bolts for vehicle or ship assembly.

Hydraulic square drive torque wrenches operate based on the principles of hydraulic pressure and mechanical leverage. Here’s a breakdown of their working mechanism:

- Hydraulic Pump: The wrench is typically powered by a hydraulic pump, which generates pressure. This pump is either manually operated, driven by an electric motor, or powered by air.

- Hydraulic Cylinder: The pump pressurizes the hydraulic fluid, which then drives a piston inside the hydraulic cylinder. The piston applies force to the internal drive mechanism of the wrench.

- Torque Generation: This force is transmitted through the wrench’s square drive, which rotates the attached socket. The amount of torque generated is directly proportional to the hydraulic pressure applied, and the system is calibrated to provide accurate readings.

- Control Mechanisms: Many hydraulic torque wrenches are equipped with torque control systems (manual or digital) that allow the user to set a desired torque value. When this value is reached, the wrench may automatically stop or give a visual or audible signal to prevent over-tightening.

- Release Mechanism: Once the set torque level is achieved, the system will release or disengage, ensuring the exact torque value is applied.

| Business Type | Exporter, Supplier |

| Feature | High Durability, Quality |

| Type | Hydraulic Torque Wrenches |

| Drive Size | 3/4 Inch |

| Brand Name | Powermaster |

| Application | Tightening and loosening process |

| Radius | Ultra Low |

| Serier | TW-H |

- ±%3 high precision torque operation

- Available from 260 to 48.500 N.m

- Hexagon cassettes from 19 to 175 mm

- Suitable for tightening and loosening process

- 360o x 360o rotatable multi-position oil inlet port

- Ultra low profile design for limited access applications

- Various cassettes and adaptors, reducer are available

- Choice of square or allen drive adapters

- Repair, maintenance and calibration services

| Business Type | Exporter, Supplier |

| Material | MildSteel |

| Color | Silver |

| Size | Multisizes |

| Packaging Type | Box |

| Specialities | Non Breakable, High Tensile, High Quality |

| Country of Origin | India |

| Business Type | Exporter, Supplier |

| Material | MildSteel |

| Surface Finishing | Polished |

| Color | Silver |

| Size | 5-10mm, 10-15mm, 15-20mm, 20-25mm |

| Packaging Type | Box |

| Specialities | Non Breakable, High Tensile, High Quality |

| Country of Origin | India |

| Business Type | Exporter, Supplier |

| Packaging Type | Box |

| Usage/Application | Agriculture |

| Material | Mild Steel |

| Type | Insulated open wrench |

| Warranty | 1 Year |

| Country of Origin | Made in India |

An **insulated open wrench** is a specialized tool designed to safely handle nuts and bolts in electrical environments where live components might be present. The insulation ensures that the user is protected from electric shocks by providing a barrier between the tool and the live electrical parts. Here’s a comprehensive overview of its features, applications, and benefits:

### **Key Features:**

1. **Insulation Rating**: - **High Voltage Protection**: Typically insulated to handle voltages up to 1000V (or higher, depending on the certification). This insulation provides a safety barrier that prevents electrical current from reaching the user.

2. **Insulated Construction**: - **Material**: The handle and potentially the entire wrench body are coated with high-quality, electrically insulating material such as plastic or rubber. - **Insulation Thickness**: Designed to meet safety standards (such as IEC or VDE), providing reliable protection against electric shock.

3. **Open-End Design**: - **Jaws**: Features open-ended jaws on one or both ends, which are used to grip and turn nuts and bolts of various sizes. - **Size Availability**: Comes in various sizes to fit different nuts and bolts, allowing for versatility in different applications.

4. **Durability and Strength**: - **Robust Construction**: Made from durable materials like forged steel, which ensures strength and long-lasting performance even under heavy use. - **Wear Resistance**: The insulated coating is designed to resist wear and tear, maintaining its protective properties over time.

5. **Ergonomic Handle**: - **Comfort**: The handle is often designed for comfort, with ergonomic features to reduce user fatigue during extended use. - **Grip**: May include a non-slip surface or textured grip to enhance control and prevent slippage, even in wet or oily conditions.

### **Applications:**

1. **Electrical Work**: - **High-Voltage Environments**: Essential for use in environments where live electrical components are present. The insulation ensures that users are protected from electric shock. - **Electrical Maintenance**: Useful for tightening or loosening electrical fittings and components safely.

2. **Industrial Settings**: - **General Maintenance**: Suitable for various maintenance tasks in industrial environments where electrical safety is a concern. - **Machinery**: Can be used on machinery and equipment where electrical components are present and need to be adjusted or serviced.

3. **Safety Compliance**: - **Regulatory Standards**: Helps in meeting safety regulations that require the use of insulated tools in environments with electrical hazards.

### **Benefits:**

1. **Safety**: - **Shock Protection**: Provides a high level of safety by insulating the user from electrical shocks, making it suitable for working with live circuits. - **Compliance**: Meets regulatory standards for electrical safety, ensuring that the tool is appropriate for use in hazardous environments.

2. **Versatility**: - **Multiple Sizes**: Available in various sizes to accommodate different nuts and bolts, enhancing its utility across different tasks.

3. **Durability**: - **Long-Lasting**: Built to withstand heavy use and harsh conditions, while maintaining its insulating properties.

4. **Comfort**: - **Ergonomic Design**: Provides a comfortable grip, reducing hand strain and improving control during use.

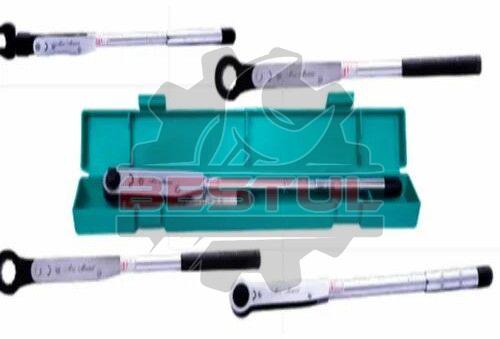

| Business Type | Exporter, Supplier |

| Drive Size | 3/4 Inch |

| Brand Name | Mac Master |

| Model Number | TW500R |

| Weight | 7.30 Kg |

| Overall Length | 6 |

| Torque Range | 135-675 NM |

| Usage | Workshop |

| Condition | New |

| Item model number | TW500R |

| Head width | 72mm |

Incepted in 1995, Mac Master Tools is an India-based company, engaged in the manufacture and export of premium quality torque wrenches, slugging wrenches, hex drivers, speed braces and other industrial tools. With its stronghold on quality and technology the company has earned a sound reputation and loyal customer base globally. The products are designed and manufactured to meet international standards for accuracy which contributes to the overall value for our customer.

A torque wrench is a tool used to apply a specific torque to a fastener such as a nut, bolt, or lag screw. It is usually in the form of a socket wrench with special internal mechanisms.

A torque wrench is used where the tightness of screws and bolts is crucial. It allows the operator to set the torque applied to the fastener so it can be matched to the specifications for a particular application. This permits proper tension and loading of all parts.

uality & Infrastructure

Incepted in 1995, Mac Master Tools is an India-based company, engaged in the manufacture and export of premium quality torque wrenches, slugging wrenches, hex drivers, speed braces and other industrial tools. Our commitment is to provide best quality industrial torque tools at most competitive prices

Our Strength

We have been able to clinch such a huge number of clients because of the quality products and services being offered to them. Our clients are spread all over the world. The excellence in the quality and wide range of products differentiates us from others.

About Mac Master

Incepted in 1995, Mac Master Tools is an India-based company, engaged in the manufacture and export of premium quality torque wrenches, slugging wrenches, hex drivers, speed braces and other industrial tools. With its stronghold on quality and technology the company has earned a sound reputation and loyal customer base globally. The products are designed and manufactured to meet international standards for accuracy which contributes to the overall value for our customer.

| Business Type | Exporter, Supplier |

| Material | Aluminium Bronze |

| Brand Name | HI-Tech |

| Size | 8 Inch |

| Type Of Tool | Spanner |

| Adjustable Range | 200 |

| Finish | Golden |

| Warranty | 1 Year |

| Surface treatment | Galvanised |

| Packaging Type | Box |

| Country of Origin | Made in India |

A non-sparking adjustable wrench is a specialized tool designed to reduce the risk of sparks in environments where flammable or explosive materials may be present. It is commonly used in industries such as oil and gas, chemical plants, mining, and other potentially hazardous areas.

The non-sparking aspect of the wrench is achieved by using materials that do not produce sparks when struck or rubbed against each other. These materials are typically made from non-ferrous alloys such as aluminum bronze or beryllium copper. These alloys have low sparking characteristics and are able to withstand the rigors of mechanical work.

When selecting a non-sparking adjustable wrench, it is important to consider the specific requirements of your work environment. Look for wrenches that are certified as non-sparking or intrinsically safe by reputable standards organizations such as ATEX or FM Approvals. These certifications ensure that the tools meet the necessary safety standards for use in potentially explosive atmospheres.

It's worth noting that non-sparking tools are typically more expensive than their traditional counterparts due to the specialized materials used in their construction. However, the added safety they provide in hazardous environments makes them essential tools for certain industries.

Certainly! Here are some additional details about non-sparking adjustable wrenches:

-

Usage: Non-sparking adjustable wrenches are used for tasks that require adjustable gripping and turning of nuts, bolts, and other fasteners. They offer the versatility of an adjustable jaw, allowing the tool to fit different sizes of fasteners.

-

Non-Magnetic: In addition to being non-sparking, these wrenches are also non-magnetic. This property makes them suitable for use in environments where magnetic materials can interfere with sensitive equipment or processes.

-

Material Options: Non-sparking adjustable wrenches are typically made from two primary alloys:

-

Aluminum Bronze: This alloy is composed of aluminum and copper, with small additions of nickel and iron. It offers excellent non-sparking properties and good resistance to corrosion, making it suitable for a wide range of applications.

-

Beryllium Copper: This alloy contains copper with a small percentage of beryllium, which provides high strength and hardness. Beryllium copper tools are more expensive but offer superior non-sparking characteristics and resistance to corrosion.

-

-

Size Range: Non-sparking adjustable wrenches are available in various sizes to accommodate different applications. They typically have a wide jaw opening range, allowing them to handle a variety of fastener sizes within a specific range.

-

Safety Considerations: While non-sparking tools are designed to minimize the risk of sparks, it's important to follow proper safety protocols when working in potentially explosive atmospheres. This includes adhering to safety guidelines, using appropriate personal protective equipment, and maintaining a clean and safe working environment.

It's crucial to select non-sparking tools that meet the specific safety requirements and standards of your industry or work environment. Always refer to the manufacturer's instructions and guidelines for proper usage, maintenance, and storage of non-sparking adjustable wrenches.

| Business Type | Exporter, Supplier |

| Material | Aluminium Bronze |

| Brand Name | HI-TECH |

| Size | 300mm |

| Type Of Tool | Wrench |

| Warranty | 1 Year |

| Color | Golden |

| Overall length | 5inch |

| Type | Non Sparking Bung Wrench |

| Application | Garage |

| Country of Origin | Made in India |

A non-sparking bung wrench is a specialized tool designed to loosen or tighten bungs on barrels, drums, or other containers. It is specifically designed for use in environments where flammable or explosive materials may be present, such as oil refineries, chemical plants, or hazardous waste facilities. The non-sparking feature of the bung wrench helps to minimize the risk of sparks and potential ignition in such hazardous environments.

Here are some key points about non-sparking bung wrenches:

-

Usage: Bung wrenches are used to open or close the bungs (plugs) that seal the openings of barrels, drums, or other containers. These containers often hold liquids or hazardous materials. Bung wrenches are designed to provide leverage and grip for turning the bungs securely.

-

Non-Sparking Properties: Non-sparking bung wrenches are made from non-ferrous alloys, such as aluminum bronze or beryllium copper, which have low sparking characteristics. These materials reduce the risk of sparks occurring when the wrench comes into contact with other surfaces, which could potentially ignite flammable substances.

-

Design Features: Non-sparking bung wrenches typically have a socket or hook-shaped end that fits over the bung, allowing for a secure grip. The wrench may have a long handle to provide leverage or a shorter handle for better maneuverability in tight spaces.

-

Material Options: Non-sparking bung wrenches are usually made from non-ferrous alloys like aluminum bronze or beryllium copper. These alloys offer excellent non-sparking properties and resistance to corrosion, ensuring the durability and longevity of the wrench.

-

Size and Compatibility: Bung wrenches come in various sizes to match different bung sizes and types. It's important to select the right size of wrench that matches the specific bungs you will be working with.

-

Safety Considerations: While non-sparking bung wrenches significantly reduce the risk of sparks, it's important to follow proper safety protocols when using them. Always ensure the work area is free from flammable or explosive materials, and wear appropriate personal protective equipment (PPE) such as gloves and eye protection. It's also important to handle the wrench with care to avoid any accidental damage or misuse.

When selecting a non-sparking bung wrench, look for reputable manufacturers and ensure that the wrench meets recognized safety standards for use in potentially explosive atmospheres.

Always consult the manufacturer's instructions and guidelines for specific details regarding the use, maintenance, and storage of non-sparking bung wrenches to ensure their safe and effective use in your particular industry or work environment.

-

Types of Bungs: Non-sparking bung wrenches are designed to work with different types of bungs or plugs commonly found on barrels, drums, or containers. These can include hexagonal or square-shaped bungs, as well as various types of threaded or non-threaded closures. It's important to choose a bung wrench that matches the specific type of bung you will be working with.

-

Adjustable Design: Some non-sparking bung wrenches feature an adjustable design, allowing them to accommodate a range of bung sizes. These adjustable wrenches typically have a sliding or rotating mechanism that allows the jaws to be positioned at different widths. This versatility makes them suitable for use with various sizes of bungs.

-

Grip and Leverage: Non-sparking bung wrenches are designed to provide a secure grip on bungs, ensuring efficient loosening or tightening. Many wrenches feature textured or grooved surfaces on the jaws to enhance grip. Some wrenches also have a longer handle or leverage-enhancing features to make it easier to apply the necessary force for turning stubborn

| Business Type | Exporter, Supplier |

| Type Of Spanner | Pipe Wrench |

| Material | Aluminium Bronze |

| Packaging Type | Box |

| Type Of Tool | Non Sparking Pipe Wrench |

| Size | 600mm/24" |

| Brand Name | Sparkless |

| Usage/Application | Industrial |

| Warranty | 1 Year |

| Color | Golden |

| Country of Origin | Made in India |

Pipe Wrench can be used for personal, domestic, and industrial purposes. The 600 mm Pipe Wrench comprises a malleable cast iron body that is very hard and good in quality. Pipe Wrench has a very good design to improve the productivity and usage of the tool. The Pipe Wrench has two jaws to get a nice and firm grip. The Pipe Wrench has hook and heel jaws. Pipe Wrench is mostly used for threading the pipes. The Wrench is mainly used for gripping, fastening, loosening, etc.

| Business Type | Exporter, Supplier |

| Usage | Garage |

| Type Of Spanner | Crow Foot Spanner |

| Size | 1-5/16 inch |

| Material | CRV STEEL |

| Packaging Type | Box |

| Brand Name | Proto |

| Model Name/Number | Proto J5342CF |

| Color | Silver |

| Warranty | 1 Year |

| Country of Origin | Made in India |

The Proto J5342CF, Proto 1/2 In. Drive Open-End Crowfoot Wrench 1-5/16 In., capable of quality performance, and endurance. The J5342CF by Proto is a must in every home, and shop; order your Proto 1/2 In. Drive Open-End Crowfoot Wrench 1-5/16 In. today! Are you interested in something else? Call us at (800) 696-7614, for anything on any other items or Proto wrenches!

| Business Type | Exporter, Supplier |

| Size | 18 inches |

| Type Of Spanner | Single Ended Spanner |

| Packaging Type | Box |

| Material | chrome-vanadium steel 31CrV3 |

| Brand Name | Gedore |

| Color | Sliver |

| Usage | Garage |

| Warranty | 1 Year |

| Part No. | 6401230 |

| Country of Origin | Made in India |

Slogging Spanners

A slogging spanner has a thick end that is designed to be used with a hammer to tighten fasteners, such as nuts and bolts to a precise torque.

Slogging spanners are also ideal to untighten fasteners which are stuck, as they pass high levels of force and vibration through to the nut or bolt when hit with a hammer.

Sometimes known as a 'hammer wrench', we sell slogging ring spanners and open end slogging spanners made

Best hardware provides all types of Slugging Wrench spanners in a quality range and in all type of varieties as best price possible

Slugging Wrench Product description

- Top-grade industrial quality for the hardest of continuous use

- For heavy-duty work

- Special sizes available on request up to 250 mm

- Up to length 435 mm made of chrome vanadium steel 31CrV3, from length 480 mm made of material C35

- * not standardised

- Acc. to DIN 7444

What is Slugging Wrench?

A Slugging Wrenchr has a thick end that is designed to be used with a hammer to tighten fasteners, such as nuts and bolts to a precise torque. Slugging Wrench are also ideal to untighten fasteners which are stuck, as they pass high levels of force and vibration through to the nut or bolt when hit with a hammer.

What do you use a Slugging Wrench for?

A Slugging Wrench has a thick end that is designed to be used with a hammer to tighten fasteners, such as nuts and bolts to a precise torque. s are also ideal to untighten fasteners which are stuck, as they pass high levels of force and vibration through to the nut or bolt when hit with a hammer.

How Slugging Wrenches are manufactured?Spanner are manufactured under proper supervision using quality tested metal and advanced technology.

Slugging Wrench spanner 1. Drop forged from high tensile alloy. 2. Machined to closed tolerances to ISO specifications. 3. Heat treated to achieve optimum Impact resistance. 4. Electroplating followed by black oxidizing to prevent from rusting. 5. Larger striking area to increase safety in use. 6. Greater sectional area for longer life. 7. Hexagon opening depth to ensure positive seating on nuts / bolts. 8. Chamferred openings for ease of location on nuts / bolts. 9. Greater offset height allows clear hammering in offset Slogging Spanners. 10. Clear marking of size and model.

Features of Best Hardware Slugging Wrenches / Striking Wrenches / Best hardware Slugging Wrenches / Striking Wrenches have the heaviest construction on the market.

- Slugging Wrenches / Striking Wrenches wall and thickness optimized for heavy impact

- Best hardware also manufactures castellated wrenches for use on GE turbines. Along with castellated wrench, GE turbine tools like castellated sockets, stack sockets, Striking Wrenches, slugging wrenches, podger spanners, slugging spanners are also manufactured.

- Hammer /Hammering Wrenches are available in all metric and inch sizes upto 9 1/4" (230 mm) A/F.

- Why Best Hardware Slugging Wrenches, Striking Wrenches, Hammering Wrenches or Castellated Wrench?Value of Slugging / Striking Wrenches: In the competitive world of today, savings matter! You get the life of the slugging wrench tools you expect at a fraction of the cost you currently pay!

- Quality of Slugging / Striking Wrenches: Large percentage of our revenues are spent in improving designs and life of our products. New innovations on products in this catalogue are world’s firsts - ONLY WITH BEST HARDWARE.

- Experience of Best Hardware for Slugging / Striking Wrenches: You need experience to handle the vast array of products like castellated wrench, slugging wrench etc. We have been in the business since 1971.

| Business Type | Exporter, Supplier |

| Packaging | Box |

| Application | Industrial |

| Model Name/Number | 31090 |

| Material | Aluminium |

| Warranty | 1 Year |

| Overall Length | 40.6 x 9.5 x 4.4 Centimeters |

| Weight | 3.79 Pounds |

| Color | Silver |

| Wrench Type | PIPE WRENCH |

| Feature | Adjustable |

- Professional strength aluminum pipe wrench is nearly 40% lighter than comparable same-size heavy-duty models with the same durability and ease of use

- Sturdy I-beam handle with full floating forged hook jaw for superior gripping and quick adjustments

- Aluminum pipe wrench has a non-stick adjustment nut, and self-cleaning threads with easily replaceable hook jaw, heel jaw, and spring assembly

- Straight pipe wrench is suitable for all forms of pipe work

- 36-inch (900 mm) pipe wrenches are ideal for pipe diameters of 2 inch (50 mm) to 3-1/2 inch (88 mm) with a pipe capacity of up to a 5 inches (125 mm)

| Business Type | Exporter, Supplier |

| Size | 12 inch |

| Material | Cast Iron |

| Size/Dimension | 1/4 to 2 1/2 in. (13 to 73 mm) |

| Usage | Leveraging of pipe,Garage ,Industrial |

| Finish | Coated |

| Warranty | 1 Year |

| Color | Red |

| Type | Chain tong wrench |

| Packaging Type | Box |

Ridgid 3229Double-End Chain Tongs, 1/4 in. to 2 1/2 in. Pipe CapacityProduct Features:

- Designed and sized to provide extra leverage for the toughest jobs

- Double-end jaw style can be reversed

- Pipe Capacity: 1/4 to 2 1/2 in. (13 to 73 mm)

- Total Length: 27 in. (686 mm)

- Chain Length: 17 1/2 in. (445 mm)

- Chain Breaking Load: 13,800 lbs. (6,260 kg)

- Weight: 11 lbs. (5 kg)

The RIDGID 3229 (92665) Double-End Chain Tongs are designed and sized to provide extra leverage for the toughest jobs. The chain tongs feature a double-end jaw style that can be reversed and have a pipe capacity of 1/4 in. to 2 1/2 in.

| Business Type | Exporter, Supplier |

| Drive Size | 1/4 Inch |

| Material | Mild Steel |

| Size/Dimension | 3" |

| Model Name/Number | C-24 |

| Brand Name | Rigid |

| Usage | Industrial |

| Socket Type | Hexagonal |

| Warranty | 1 Year |

| Finishing | Color Coated |

| Length Of Chain | 500mm |

Designed for extremely tight, confined areas, the RIDGID C-24 Heavy-Duty Chain Wrench is built to handle the toughest of plumbing jobs. The chain wrench is equipped with a double jaw for fast, ratchet-like action in either direction. Built to last, it features replaceable jaws made of tough alloy steel that extend the life of the wrench. A versatile plumbing tool, this chain pipe wrench has a 3 in. rated pipe capacity (5 in. actual O.D capacity) and 20-1/4 in. chain length.

- Designed with a double jaw for fast, ratchet-like action in either direction

- Heavy-duty model has replaceable, tough alloy steel jaws help to extend the life of this RIDGID chain wrench

- Chain wrenches are ideal for extremely tight work areas where other pipe wrenches won't fit

- Chain wrench has a 3 in. rated pipe capacity, 5 in. actual outer diameter capacity and 20-1/4 in. chain length

- Rugged construction and strong jaw provide maximum grip in tight, confined areas

- To prevent rusting, keep chain and jaw well lubricated with oil and store in a dry place