| Business Type | Exporter, Supplier |

| Application | Industrial |

| Material | Mild Steel |

| Brand Name | BESTLIFT |

| Click to view more | |

Product Details

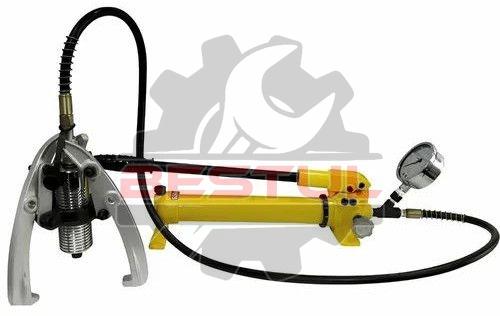

A hydraulic puller with a separate hand pump is a tool used for removing components that are press-fitted or tightly secured, such as gears, bearings, or pulleys. The design typically involves two main parts:

-

Hydraulic Puller: This part consists of the pulling mechanism itself, which is attached to the component you want to remove. It usually has arms or jaws that grip the component and apply force to pull it off.

-

Separate Hand Pump: This is a manual pump used to generate hydraulic pressure. It's connected to the puller via hydraulic hoses. By operating the hand pump, you create hydraulic pressure that is transmitted to the puller, which then exerts the force needed to separate the component from its housing.

Benefits of a Hydraulic Puller with Separate Hand Pump

-

Increased Force: Hydraulic pullers can generate much more force than manual or mechanical pullers, making them suitable for larger or more stubborn components.

-

Precision: The separate hand pump allows for controlled application of force, reducing the risk of damaging the component or surrounding parts.

-

Versatility: The separate pump can be used with various pullers, and you can often switch between different puller heads or attachments depending on the job.

-

Ease of Use: Using a hand pump requires less physical effort compared to mechanical pullers or other manual methods.

Common Uses

- Automotive Repairs: Removing gears, pulleys, or bearings from shafts.

- Industrial Maintenance: Extracting components from machinery or equipment.

- Construction: Removing parts from heavy machinery.

Safety Tips

- Ensure Compatibility: Make sure the puller and hand pump are compatible and rated for the force you need.

- Check for Wear: Regularly inspect hoses and connections for leaks or damage.

- Use Proper Techniques: Follow the manufacturer’s instructions for setup and operation to avoid accidents.

If you have any specific questions about using or maintaining this tool, feel free to ask!